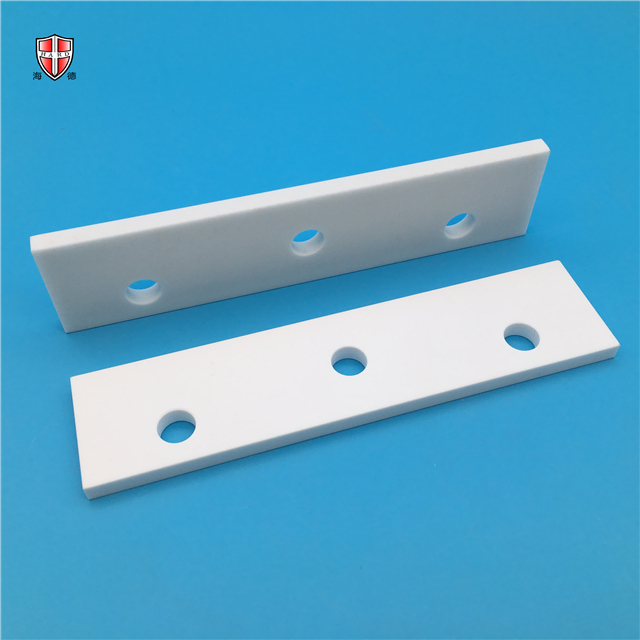

grinding milling heat sink 95% Alumina Ceramic Bar

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The heat transferred by the medium to the surface of the green body and the heat required for the vaporization of dry water, so the surface temperature of the green body remains unchanged, which is equal to the wet bulb temperature of the medium. The drying rate is stable, so it is called the constant speed drying stage. This stage is to discharge unbound water, so the body will shrink in volume, and the amount of shrinkage has a linear relationship with the amount of water reduction. If the operation is improper and the drying is too fast, the body is very easy to deform , Cracking, resulting in dry waste. At the end of the constant speed drying stage, the moisture of the material decreases to a critical value. At this time, although the interior of the material is still unbound water, bound water begins to appear in the surface layer. Slow drying stage, this stage In the middle, the water content of the body is reduced, the internal diffusion speed can not keep up with the surface water evaporation rate and the external diffusion speed, the surface no longer maintains moisture, and the drying rate is gradually reduced. Due to the reduced heat required for surface water evaporation, the temperature of the material begins to gradually increase. The partial pressure of water vapor is less than the partial pressure of saturated water vapor at the surface temperature. At this stage, the combined water is discharged, and the body does not shrink in volume and does not produce dry waste products. When the moisture is balanced, the drying rate becomes zero and the drying process is terminated. Even if the drying time is extended, the moisture of the material will not change. At this time, the surface temperature of the material is equal to the dry bulb temperature of the medium, and the partial pressure of water vapor on the surface is equal to the water vapor of the medium The drying speed in the reduced speed drying stage depends on the internal diffusion rate, so it is also called the internal diffusion control stage. At this time, the structure, shape, size and other factors of the material affect the drying rate. 2.3 The factors that affect the drying rate affect the drying rate The factors are heat transfer rate, external diffusion rate, and internal diffusion rate. (1) Accelerating the heat transfer rate To accelerate the heat transfer rate, we should do ...

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.