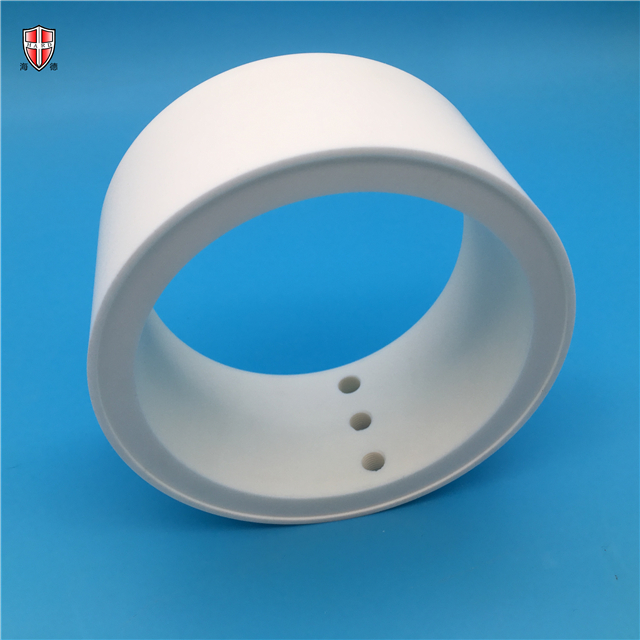

99% 99.5% Alumina Ceramic bush cylinder customized

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic is a very widely used mineral raw material. It plays a specific and irreplaceable effect in different industries. Here are a few common uses:

1) Rubber: Calcined talc is used as a plasticizer in rubber plastic resins, especially in foamed products, which can help its processing and molding. Whether it is compression molding or extrusion molding during processing, it can promote shortening of molding time. increase productivity.

Calcined talc powder in rubber resin can change the physical properties of the product-increase tensile strength, impact strength, shear strength, disturbance strength, hardness, reduce deformation, elongation, cushion expansion coefficient, etc. Calcined talc powder is used to improve the processing performance of rubber, plastic, resin, such as stamping, calendering, extrusion, and injection, and can replace 10-15% of the more expensive rubber materials to reduce raw material costs.

2) Paint: Calcined talc powder is resistant to direct sunlight and high temperature in paints and coatings, does not change color under ultraviolet light, can maintain the original gloss and color for a long time, has good resistance to acid and alkali corrosion, and water resistance Good performance, stain resistance, aging resistance, wear resistance, steam and chemical stability, and strong flame resistance

3) Ceramics: In the ceramics industry, talc has an extremely important role. An important factor in the different colors of ceramics is the addition of talc. Different proportions and different composition ratios can make ceramics show different colors. Enhanced whiteness, uniform density, good gloss, and smooth surface. In addition to the production of special block talc porcelain, it is also widely used; talc powder is combined with porcelain clay to produce special ceramic products with various properties. For example: 15% talc powder for daily-use ceramics (tableware) is tough, translucent, and bright in color, and 40-80% talc powder for building ceramics (tiles, tiles, porcelain, etc.) has minimal thermal and wet expansion. It has the characteristics of high strength, high intensity, no cracking and beautiful color. Different kinds of talc can be used to obtain different characteristics in ceramics.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.