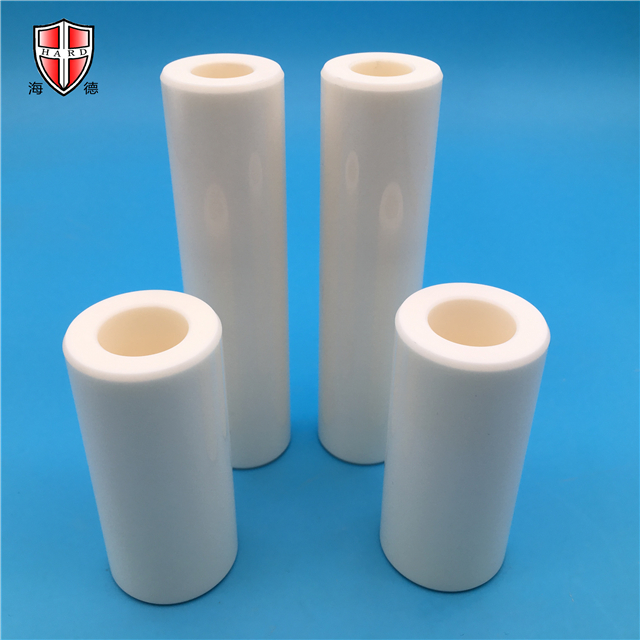

poliert aluminiumoxidkeramik alumina tube rohr manga sleeve

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The drying of ceramics is one of the very important procedures in the production process of ceramics. A large part of the quality defects of ceramic products are caused by improper drying. The drying in the ceramics industry has experienced natural drying and room-type drying, until now Continuous dryer, far-infrared dryer, solar dryer and microwave drying technology of various heat sources. Although drying is a relatively simple technology, it is widely used in industrial processes, which is not only related to the product quality and yield of ceramics. It also affects the overall energy consumption of ceramic enterprises. According to statistics, the energy consumption in the drying process accounts for 15% of the total industrial fuel consumption, and in the ceramics industry, the energy consumption for drying accounts for much more than the total fuel consumption. Therefore, energy saving in the drying process is a major issue related to energy conservation in enterprises. Fast drying speed, energy saving, high quality, and no pollution of ceramics are the basic requirements for drying technology in the new century. 2 Mechanism of ceramic drying process 2.1 Moisture in the green body The moisture content is generally between 5% and 25% .The combination of the body and the moisture, the changes in the material during the drying process, and the factors affecting the drying rate are analysis and improvement. The theoretical basis of the dryer. When the body is in contact with stationary air of a certain temperature and humidity, it is bound to release or absorb water, so that the water content of the body reaches a certain equilibrium value. As long as the state of the air is unchanged, the The moisture content of the water will no longer change due to the increase in contact time.This value is the equilibrium moisture of the green body in this air state.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.