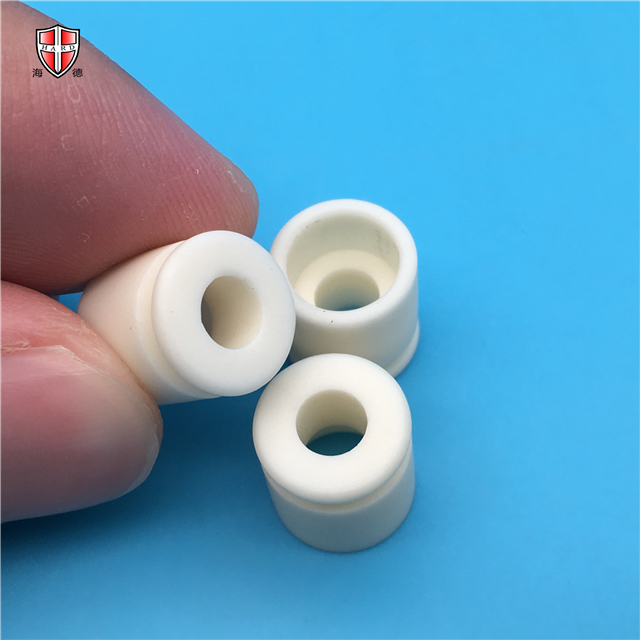

custom injection moulding Alumina Ceramic machinery parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Aluminum Nitride Ceramic nickel reduces the cold work hardening rate of austenitic stainless steel, and reduces the room temperature and low temperature strength of steel, and improves the plasticity. The increase in nickel content is beneficial to the cold forming performance of austenite stainless steel. It can reduce or even eliminate the delta ferrite in 18-8 and 17-14-2 chromium-nickel austenitic stainless steels, thereby improving its hot workability. However, the reduction of delta ferrite will affect the weldability of these steels. It is unfavorable to increase the tendency of welding hot cracking wires. In addition, nickel can significantly improve the hot workability of chromium-manganese-nitrogen (chromium-manganese-nickel-nitrogen) austenitic stainless steel, thereby significantly increasing the yield of steel. In austenitic stainless steel, The addition of nickel and the increase in nickel content lead to an increase in the thermodynamic stability of steel. Therefore, austenitic stainless steel has better rust resistance and resistance to oxidizing media, and as the nickel content increases, it is resistant to reducing media The performance of the austenitic stainless steel has been further improved. It is worth pointing out that nickel is the only important element to improve the resistance of austenitic stainless steel to many media through crystal stress corrosion. The influence of nickel on the corrosion resistance of austenitic stainless steel in various acid media needs to be pointed out Under some conditions in high temperature and high pressure water, the increase in nickel content leads to an increase in the intergranular stress corrosion sensitivity of steel and alloys, but this adverse effect will be reduced or inhibited due to the increase in chromium content in steel and alloys. As the nickel content of magnetic card austenitic stainless steel increases, the critical carbon content for intergranular corrosion decreases, that is, the intergranular corrosion sensitivity of steel increases. As for the resistance to pitting corrosion and crevice corrosion of austenitic stainless steel, nickel The effect is not significant. In addition, nickel also improves the high-temperature oxidation resistance of austenitic stainless steel. This is mainly due to the improvement of the composition of the chromium oxide film, the structure and performance of the nickel, and the higher the nickel content, the more harmful it is. It is caused by low melting point nickel sulfide at the grain boundary in steel. Generally speaking, simple chromium-nickel (and chromium-manganese-nitrogen) austenitic stainless steel is only used for use conditions that require rust resistance and oxidation resistance media (such as nitric acid, etc.) Next, as an important alloying element in austenitic stainless steel, molybdenum is added to steel to further expand its use range. The role of molybdenum is mainly to improve steel's reducing medium.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.