diverse PCB ceramic heat sink radiating substrate slice

Reputation depends on quality, quality comes from Hard!

Ceramic Substrate:

At present, there are five types of ceramic heat-dissipating substrates: HTCC, LTCC, DBC, DPC, and LAM. Among them, LAM belongs to the patented technology of Slyton and Huazhong University of Science and Technology National Photoelectric Laboratory. HTCC\LTCC belongs to the sintering process, and the cost will be Higher.DBC and DPC are the professional technologies that have been developed and matured in recent years in China. DBC Diverse Pcb Glass Ceramic Bars Ceramic Heat Sink Radiating Substrate Slice uses high temperature heating to combine Al2O3 with Cu plate. The technical bottleneck is that it is difficult to solve the problem of micropores between Al2O3 and Cu plates. This makes Diverse Pcb Ceramic Heat Sink Radiating Substrate Slice the mass production energy and yield of the product more challenging. The DPC technology Diverse Pcb Ceramic Heat Sink Radiating Substrate Slice uses the direct copper plating technology to deposit Cu on the Al2O3 substrate. The process Plate Silicon Nitride Disc combines materials and thin film process technology. The most commonly used ceramic heat sink substrate in recent years. However, its material control and process technology integration capabilities are relatively high, which makes the technical threshold for entering the DPC industry Glass Ceramic Bars and stable production relatively high. LAM technology is also known as laser rapid activation metallization technology.

Application:

The role of ceramic substrate ceramic substrate according to the field of ceramic substrate application, is divided into HIC (hybrid integrated circuit) ceramic substrate, focusing potentiometer ceramic substrate, laser heating fixing ceramic substrate, chip resistor substrate, Network resistor substrate, etc.; according to different processing methods, ceramic substrates are divided into two types: molded tablets and laser scribe films. The ceramic substrate in the chip resistor substrate is a part of the chip resistor. The upper layer of the substrate is coated with different semiconductor materials, and then copper is plated on both ends for soldering. The biggest advantage of the whole resistor is that the volume can be made very well. small.

Company Information:

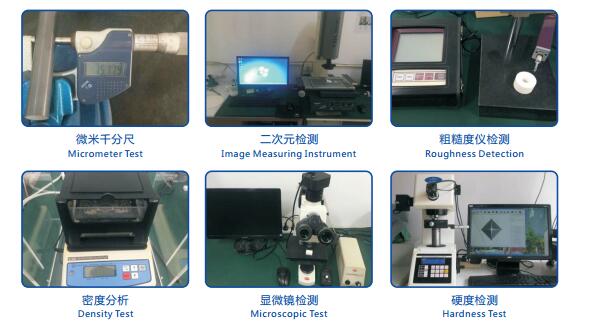

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Show time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

Factory Show

Our Team

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.